August 2010

Welcome!

Dear Customers,

We hope you have had time to enjoy the summer and some days off to re-charge the batteries, ready for the peak season.

The big question is how big will the peak be and for how long will it last? It started early this year but the container urgency to deliver sound containers for export from China seems to have softened a bit.

We nevertheless hope the high export numbers will continue and Brigantine confirms we are ready to handle your volume effectively and in a speedy way. Part of our latest re-organization has indeed been to take waste out of the system and ensure we deliver the best service and quality in the market within the EMR field.

We also urge you to let us know of any dissatisfactions you might have and help us to become better and continuous to improve our services and quality. “A good customer (business partner) tells you and does not just move business away”.

We have also changed shareholder as you might have seen from the news. In the past Brigantine was owned 100% by Maersk Hong Kong Ltd., but in order to create a truly arms length from our customer Maersk Line and serve the market as a common EMR service provider, our new shareholder is APM Terminals.

This will also entail more synergies which in return will benefit APMT’s and Brigantine’s customers going forward.

Please contact us should you have any specific requirements or suggestions that could expand our business relationship. We are ready to handle your volumes.

Thank you very much and enjoy the rest of the summer.

Yours faithfully,

Paul Erik Andersen

Chief Commercial Officer

Email: paul.erik.andersen@brigantinegroup.com

HEMPEL Paint Grouping Order

Nowadays, the competition in container repairing industry becomes much fiercer due to low entry barrier and market saturation. The shipping companies reduce their repairing budget without proportionately lowering their repairing standard. How to make profit becomes a question every container repairing company is asking and considering. Cost saving is the only way to go. Let’s share our customers’ concerns when we are recommending HEMPEL paints to them.

“We’d like to order HEMPEL paints. It’s a great brand with good quality and also requested by the shipping companies.”

“However, we don’t want to keep stock of repairing materials, like paints. Who knows how many containers our customers will ask us to repair next month?”

“We are a middle-sized depot and cash flow ratio is an important KPI to us.”

“Neither would we like to order 1,000 liters of paints at one time, nor would we like to afford the transportation charge.”

“Only if we didn’t need to pay for the transportation charge for less than 1,000 liters, we’d like to order HEMPEL paints from you.”

The situation is quite clear. Every depot is trying to keep using the best material, like HEMPEL paints, but maintain the lowest possible operational cost.

How to meet the requirement of our customers? We come up with a solution called “HEMPEL Paint Grouping Order”. We check with each customer about the paint quantity they would like to order regularly and then group these orders for the same area into one as one delivery booking. In this way, no matter how many liters each customers orders at one time, none of them needs to pay the transportation charge. Meanwhile, each customer can keep their stock at reasonably level with minimal cost. This is a win-win-win solution for vendor, end-user and Brigantine.

We have started the “HEMPEL Paint Grouping Order” in Shanghai, Tianjin, Ningbo, Dalian, Xiamen, Qingdao and the detailed schedule is as below:

Area |

Order Collection date per month |

Shanghai |

1st, 15th |

Tianjin |

2nd, 16th |

Ningbo |

4th, 18th |

Dailian |

5th, 19th |

Xiamen |

7th, 21st |

Qingdao |

8th, 22nd |

No matter how many liters of HEMPEL paints you need in any of these areas, please do not hesitate to call Ms. Mary at +86 755 2527 9996 or Ms. Mia at + 86 755 2527 9171. Trust you do not want to miss any chance to be able to use premium paint with the lowest cost for your business!

Corten Steel versus Mild Steel

Containers are mainly made by hot rolled weathering corten steel, which is a special alloy steel featured with high intensity and resistance of cauterization by atmosphere and ocean. Corten steel is widely used in container manufacturing and repairing. As compared with mild steel, corten steel has more excellent characteristics.

I).The mechanical characteristics are decided by the composition. Below is comparison of chemical composition between corten steel and mild steel.

Technical Data |

Chemical Composition |

|||||||

C |

Mn |

P |

S |

Si |

Cu |

Cr |

Ni |

|

Corten Steel |

0.12 max |

0.20-0.50 |

0.07-0.15 |

0.05 Max |

0.24-0.75 |

0.25-0.55 |

0.30-0.12 |

0.65 Max |

Mild Steel |

≤0.20 |

≤1.50 |

≤0.04 |

≤0.04 |

0.55 |

|

|

|

II). Because of different chemical composition, corten steel is more corrosion resistant than mild steel, with below features:

- Resistance to Atmospheric corrosion

- Resistance to Sulfuric Acid corrosion

- Resistance to Seawater corrosion

-

Initial oxide film is formed on surface of corten steel, which is compact and consistent; no cracks or loose appeared. It prevents steel metal surface from further corrosion, while mild steel does not have this character.

-

The extra metal elements in corten steel will form non-crystal structure under the initial oxide film, which will separate steel metal from atmosphere and seawater.

-

Corten steel is more easily consolidated with surface painting and can last longer time. It well protects the surface corrosion from expanding further.

When exposed to same environment in the same time, corten steel and mild steel appear different features with below results:

Steel |

Rust thickness |

Rust average thickness |

Appearance features |

Corten Steel |

4.0 um ~8.0 μm |

7.0 μm |

compact、flawless、Solid |

Mild Steel |

8.0um~17.0 μm |

12.5 μm |

Loose 、desquamate |

III).Excellent character of corten steel can also be seen from the physical characteristics.

Technical Data |

Tensile Test |

Impact Test |

Bend 180°Test |

Weight |

||

Tensile Strength Limit |

Yield Strength Limit |

Yield Ratio |

(ISO-V) |

d=1.0a |

(kg/cm3) |

|

(MPa) |

(MPa) |

(%) |

||||

Corten Steel |

490 |

350 |

22 |

>27 |

d=a~2a |

7.85 |

Mild Steel |

410 |

250 |

21 |

|

|

7.85 |

The cutting and processing of corten steel and mild steel are the same for the container repairing. Arc welding, touching welding and air protecting welding can be adapted for both corten steel and mild steel. Only in cold bending of container manufacturing, larger bending strength is needed for corten steel.

The stronger mechanical characteristics of corten steel make it being widely used in container building and container repairing industry.

IV).Cost Comparison of Corten Steel and Mild steel

Generally speaking, price of corten steel is 10% higher than that of mild steel. However, container owner companies still prefer to use corten steel for repairing, as it is more cost effective than mild steel in the long term.

- In natural circumstance, thickness decrease of mild steel caused by corrosion is above 0.1-1mm within 5 years. Condition will be more serious in heavily polluted environment. Due to different chemical composition, corrosion to corten steel is less, which extends life span of corten steel products.

- Because of surface oxide film, painting can be applied easily to corten steel, which reduces paint consuming. It is estimated that painting and maintenance cost within 10 years of mild steel product can be 3 times of corten steel. In this way, corten steel reduces material cost. Also, validity of painting on corten steel is much longer than that on mild steel, which decreases painting times and improve efficiency.

Excellent corrosion resistance, longer life span and lower maintenance costs etc. make corten steel more cost saving than mild steel. Brigantine is only using Corten steel unless our customer specify otherwise.

Should you have any queries, please do not hesitate to call Ms. Mary at +86 755 2527 9996 or Ms. Mia at + 86 755 2527 9171.

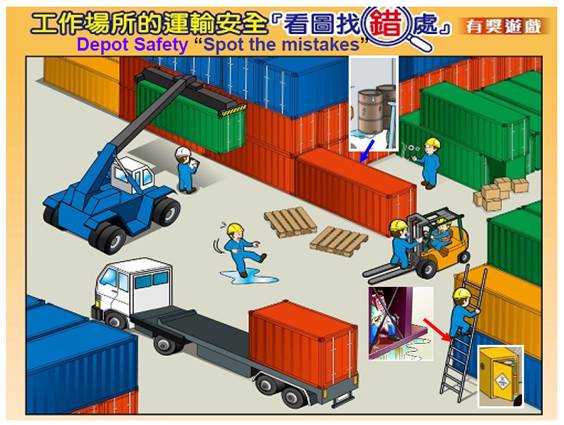

HSSE Knowledge Quiz

To test your occupational health and safety knowledge, you only need to circle at least TEN risks as shown in the picture. Then you will have the chance to participate in the lucky draw.

『Spot the mistakes』

(Please print and circle at least 10 risks as shown in the picture, then cut if off along the broken line.

--------------------------------------------------------------------------------------------------------------------------

Reply Form

Company:________________Name: Contact No:_______________

Mailing Address:_________________________________________________________

Important Notice :

- Please send your answers to Brigantine QHSSE department by email: edmond.leung@brigantinegroup.com before 25 Oct 2010.

- Please state clearly your company name, your personal valid contact phone number, and full mailing address on your mail.

- Brigantine QHSSE department will award one mysterious gift to twenty winners by lucky draw from the participants with all answers correct in Nov 2010.

- Brigantine QHSSE staff will contact and mail the gift to the final winners.

- Should you have any queries, please don’t hesitate to contact Mr Edmond Leung of Brigantine QHSSE department at +852 3765 7760 or email to edmond.leung@brigantinegroup.com.

- Brigantine QHSSE department reserves the final decision of the quiz if any dispute.

Answer of HSSE Knowledge Quiz – Apr 2010 1.(H) 2.(D) 3.(E) 4.(B) 5.(I) 6.(C) 7.(G) 8.(A) 9.(J) 10.(F)

|